By Elizabeth Kasprick

This past may we were excited to take part in the American Association of State Transportation Officials (AASHTO) Spring Meeting in Seattle, where we were able to share some of the innovative practices we’ve been working on.

Our Innovations Day featured 13 interactive tables and displays. Between sessions, conference attendees had the opportunity to learn about innovations from across our agency and chat with our staff. It was an excellent opportunity to connect with people and brainstorm new ways to apply these ideas.

|

| Conference attendees browse our Innovation Day tables at the AASHTO spring meeting in Seattle |

Here are some of the highlights.

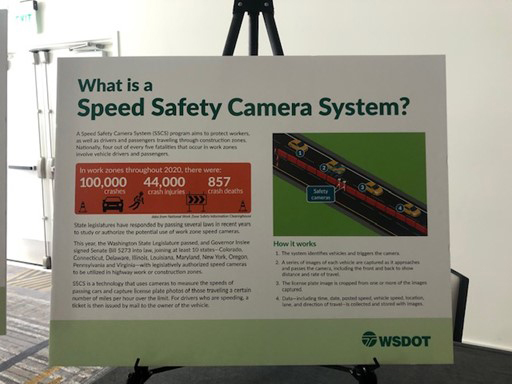

Speed safety camera system to increase work zone safety

The Speed Safety Camera System is a tool to increase safety for crews in work zones, always a top priority for us. In summer 2021, speeds in several counties showed an average increase of 10% over those driven for the same days in 2019. For King, Pierce and Snohomish counties between March and July, daily speeds averaged 12% higher compared to pre-pandemic levels. This has a significant affect on our work zones. According to crash data from the Washington State Patrol, almost 20% of the work zone collisions reported in 2020 can be attributed to high speed alone. Higher speeds in work zones can often lead to more severe injury and fatalities.

Speed Safety Camera Systems allow the Washington State Patrol to remotely enforce reduced speed limits and change driver behavior. Earlier this year the Legislature approved the use of cameras in work zones and they will go live in July 2024.

|

| Implementation of speed cameras in work zones starting July 2024 will help keep our crews and the public safe |

Planning and studies to be more inclusive and diverse

We saw multiple projects emphasizing inclusion and diversity. The Interstate 405/State Route 167 Program equity and mobility dashboards study the travel patterns of communities within the I-405/SR 167 corridor. The Office of Equity and Civil Rights promoted their work to advance Washington’s Pro-Equity and Anti-Racism (PEAR) work and shared information regarding our Diversity, Equity, and Inclusion Plan, the Diversity Advisory Groups and the Culture of Belonging Program.

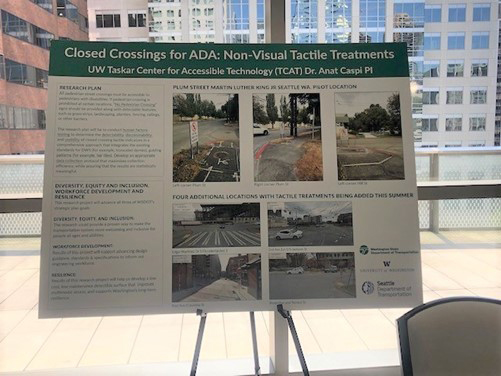

We are also bringing a more inclusive lens to planning future non-visual ADA pavement treatments for closed crossings. Using the color red and visible, raised texture, closed crossings, pavement markings would provide a clearer delineation for people with all ranges of vision. The Development Division is partnering with the University of Washington and City of Seattle in a research study to determine best treatment options, gather feedback from the disability community on the overall effectiveness of the tactile application and establish a future standard specification for closed crossing non-visual treatments. This work will involve applying non-visual pavement treatments to five intersections in the downtown corridor.

|

| Exploring non-visual ADA pavement treatments for closed crossings in downtown Seattle |

Increasing our capacity to be environmentally resilient

We are taking a new approach to stormwater management that builds environmental resilience with the Puget Sound Gateway SR 167 Riparian Restoration Program (RRP). The RRP is an integrated, holistic approach to meeting regulatory requirements in ways that provide greater environmental benefits than traditional mitigation methods. The RRP, in combination with associated roadside restoration areas, encompasses 176 acres on both sides of I-5 in Fife and Milton, and segments of the new SR 167 corridor in Tacoma and Pierce County. The RRP will restore land altered by previous uses, mitigate stream and wetland impacts, and provide floodplain management for Hylebos Creek and other tributary streams in the project area. When complete, the project will reduce flood levels and improve degraded in-stream, riparian and floodplain habitats, and provide long-term benefits to fish and wildlife.

Taking new approaches to existing practices

A testament to the desire to build and improve on processes can be seen in the Moveable Sign Fabrication System. The two-person sign installation team working out of our Union Gap sign shop, is responsible for building and installing signs along highways in the region. This team identified the need for a new way to assemble and fabricate the large sign panels. They needed a table that could adjust to the height of the sign during fabrication. The team designed a hybrid model to fit their needs – a table with easy adjustment to efficiently build signs with less physical demand. The benefits of using the movable sign fabrication table are it requires less physical strain and improves sign fabrication efficiency. This is an innovative practice that we are already replicating due to the success of this approach.

|

| A movable sign fabrication system was developed by our own sign shop team |

Innovation Challenge Program

Some of these innovations were made possible through our Innovations Challenge sponsored by the Maintenance and Operations Division. The Innovations Challenge program is open to all full-time maintenance and operations employees. Entries are accepted throughout the year and an annual cash prize is awarded both to the nominee and their corresponding maintenance area budget! Categories for the innovations challenge include tools and equipment, technology best practices and techniques best practices. This is just one way that we continue to encourage and advance innovations!

|

| Our staff was excited to share some of our work at May’s AASHTO conference |

No comments:

WSDOT comment policy

Post a Comment