By: Tina Werner

You may be wondering what WSDOT has to do with invasive species, and the answer may surprise you. Invasive plants hitchhike on vehicles and spread along our highways. They can affect everything from farming to recreation. Some of them are even very flammable, which can be a wildfire risk.

Governor Ferguson proclaimed February 24-28, 2025, as Invasive Species Awareness Week in Washington.

Our state highways and byways play a role in the spread of invasive species. There are over 100,000 acres of state roadside across Washington. These corridors unintentionally serve as pathways for travelers that we don’t want. Plants, animals and insects can spread from the roads and rails to public and private lands. We play a key role in protecting natural resources from invasive species. Here’s how it happens:

- Invasive Plants: Weeds and other invasive plants often hitch a ride on vehicles from other states. Once they take root along our roadsides, their seeds can blow into nearby lands - both public and private. These non-native plants are a threat to agriculture and recreational areas. Some of them are very flammable and can add to the risk of roadside wildfires.

- Aquatic Invasives: You might not think of freshwater mussels cruising down the highway. But non-native species from the water can travel on boats moving along our highways. From there, they can infest our lakes and rivers. These species can affect hydroelectric power, irrigation for farmland, fishing and salmon habitats. We partner with the Department of Fish and Wildlife to address this. Boaters must stop at checkpoints for inspection.

- Invasive Insects: Insects like the Spotted Lanternfly and the Emerald Ash Borer also hitchhike across the country. These insects can devastate native trees. They also create physical hazards on our highways when weakened trees fall onto the roads.

We need your cooperation to manage and prevent the spread of invasive species. Stop at checkpoints. Clean your vehicles. Report invasive species if you see them. We can all contribute to saving our state’s natural resources.

|

| Highway corridors act as wind tunnels. This is a section of I-90 near Spokane. You can see the Rush Skeletonweed . This plant’s seeds blow along our highways and then out into the surrounding land. |

|

| This roadside fire started along the frontage road next to US 12 near Wallula. The low growing blond colored grass shown in the foreground is Cheatgrass and was the source of ignition. |

The challenge with weed control

Our challenge is to prevent weeds on our roadsides. In cases where the weeds are already there, we aim to control their spread. Our maintenance team has certified and trained experts on staff who monitor and treat them throughout the state. Still, these efforts only skim the surface. We know that the weeds are gaining on us every year.

Addressing the roots – a possible solution

We have one of the most advanced management systems in the country for this work. Our maintenance crews use high-tech location and mapping solutions to track invasive species. However, our maintenance program has been underfunded for decades. We have to prioritize life-safety tasks like guardrail repairs or bridge deck work with our limited maintenance resources. We also apply for research grants and other special funding to supplement our limited funding.

The proof is in the pudding

We want the roadside to have plants growing that are the same as the surrounding areas. Where possible, this includes plants that are loved by pollinators. Once native vegetation is well-established, weeds have less chance to take root.

Still skeptical if this even works? If you are out traveling our state, keep an eye out for a couple of our more recent projects.

- Pollinator Habitat and Carbon Sequestration at the Scatter Creek Rest Area: If you're traveling northbound on I-5 in Thurston County, you’ll pass by meadow test plots that were completed in fall 2024. These plots help create habitats that are friendly to pollinators. They also help remove carbon from the air by holding it in trees and soils. It’s a great example of how we are working to support environmental sustainability.

|

| Part of the team helping with prairie meadow plantings at the northbound I-5 Scatter Creek rest area. Over 500 native oak trees were planted during this effort. |

|

| Drone technology captures pollinator meadow test plots installed at the northbound I-5 Scatter Creek Rest Area in 2024. Plants are expected to emerge in spring of 2025. |

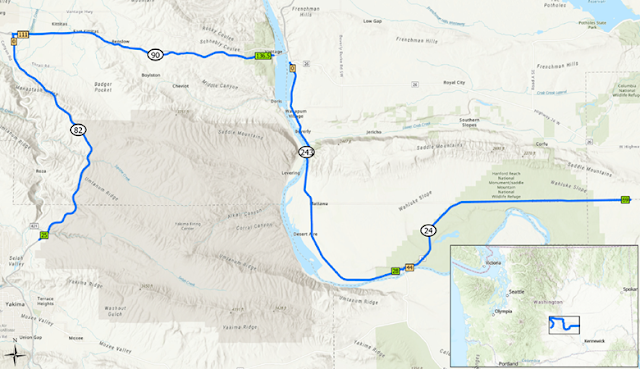

- Non-Native Annual Grass Control for Fire Prevention in Central Washington: If you're driving through Eastern Washington, you may notice areas where there’s less cheatgrass. Specifically, on I-90 between Ellensburg and Vantage, or I-82 between Ellensburg and Selah. The technical name for this flammable invasive grass is Downy Brome. We treated the roadside in fall 2024. We used a new type of herbicide that is only active in the soil. It targets invasive species without harming native bunch grasses and shrubs. Not only are those native plants an important part of the ecosystem, they are also less flammable. The herbicide suppresses annual weeds and grasses for up to four years, allowing them to succeed potentially in a drought. That means that even once the herbicide’s effects wear off, the Downy Brome is less likely to gain a foothold. Working together, all of these things contribute to healthier, more resilient landscapes.

|

| A map of the roadside sections in Central Washington treated in fall 2024 for suppression of flammable non-native annual grass and weeds. |

More information about how we maintain vegetation along state highways is available online, including how we protect pollinators.